by Athina Bardho

Germany is globally renowned for its engineering prowess, and its influence extends far beyond automobiles and heavy machinery. The German textile machinery sector seamlessly blends precision engineering with the artistry of fashion, revolutionizing the way fabrics are produced and enhancing the aesthetic potential of garments. With a Gross Domestic Product (GDP) of €4,186 billion in 2023, Germany holds its position as the largest economy in Europe and the third-largest globally, behind only the United States and China (Glunz, 2020). Among its major exports, textile machinery stands out as a cornerstone of the nation’s technological innovation.

German engineering has propelled the textile and fashion industry into a new era of efficiency, sustainability, and creative possibility. From nonwoven fabrics for industrial use to delicate materials for high fashion, German machinery has played a crucial role in crafting textiles that define global trends. The precision and ingenuity inherent in German engineering continue to shape how the fashion world develops, ensuring that the textile industry remains at the forefront of global innovation.

- From Weavers to Wonders: A Brief History of German Textile Machinery

- The Role of Textile Design in Fashion

- Global Reach and Market Dynamics

- Sustainability in Textile Machinery

- Future Prospects: Technology Meets Tradition

- Engineering Elegance for a Sustainable Tomorrow

- Titans of Technology: Germany’s Leading Players

- How German Engineering Advances Sustainable Fashion

- What Makes German Machines Stand Out?

- Sewing the Future: Innovation in Action

- Untangling Challenges: What Lies Ahead for German Machinery

- Engineering Tomorrow’s Trends

From Weavers to Wonders: A Brief History of German Textile Machinery

The roots of Germany’s textile innovation date back to the Industrial Revolution, where the introduction of mechanized looms set the stage for modern textile production. Over time, German manufacturers became synonymous with precision, durability, and innovation, particularly in the field of technical textiles.

By focusing on technically demanding textiles and innovative products, Germany now dominates the technical textiles segment, holding a 45% market share globally. This success stems from close collaboration with research institutions and the ability to integrate complex industrial solutions (Fibre2Fashion, 2014). Despite challenges such as fluctuating raw material costs, the German textile machinery industry has managed to maintain its competitive edge by pivoting toward sustainability and energy efficiency.

The Role of Textile Design in Fashion

At its core, textile design is the foundation of fashion. German machinery enables designers to push the boundaries of creativity, providing tools to produce custom prints, intricate weaves, and versatile knits that inspire avant-garde designs. Techniques like embroidery and digital printing offer designers endless opportunities to experiment, ensuring their collections stand out in a crowded marketplace.

For example:

- Embroidery: German machines facilitate the creation of intricate patterns with unparalleled precision.

- Weaving: Advanced weaving machines from Germany enable the production of customized fabrics, ranging from traditional jacquards to experimental textiles for technical applications.

Image by Dornier Lindauer DORNIER GmbH via https://www.lindauerdornier.com/en/weaving-machines/

The synergy between textile design and machinery highlights the role of technology in driving fashion innovation, ensuring that designers have the tools to bring their visions to life with unmatched precision and creativity.

Global Reach and Market Dynamics

German textile machinery has a strong presence in global markets, with Asia accounting for 40% of its exports. Countries like China, India, Turkey, and the United States are major importers, leveraging German technology to enhance their domestic textile industries. As demand for high-quality textiles grows, so does the reliance on cost-effective, sustainable, and innovative German machines (Fibre2Fashion, 2014).

2

main competitors fall short (ITALY, SWITZERLAND)

4

major importers (CHINA, INDIA, TURKEY, USA)

40%

of global presence in asian countries

Interestingly, Germany’s closest competitors, Switzerland and Italy, fall short in terms of turnover and sustainability standards. The longevity and reliability of German machinery make it a preferred choice for countries aiming to reduce long-term costs while maintaining superior production quality.

Sustainability in Textile Machinery

Sustainability is no longer a trend but a necessity, and German textile machinery leads the way in addressing environmental concerns. From reducing energy consumption to enabling the use of eco-friendly raw materials, German machines are built to meet the demands of a more conscious fashion industry.

For instance:

- Innovations in nonwoven textiles have revolutionized industries like automotive and medical, creating durable products with minimal waste.

- The VDMA Textile Machinery Association continues to advocate for environmentally responsible production methods, ensuring that German manufacturers stay ahead of global sustainability standards.

German innovation in sustainability not only improves the environmental footprint of the fashion industry but also demonstrates how technical textiles can contribute to industries beyond fashion, driving global sustainability efforts.

Future Prospects: Technology Meets Tradition

The future of German textile machinery lies in the integration of digital technology and artificial intelligence. As demand for technical textiles grows, particularly in industries like healthcare and mobility, German manufacturers are poised to remain leaders in innovation. Moreover, advances in smart textiles and 3D knitting are expected to redefine fashion, blending form and function in unprecedented ways. By combining traditional craftsmanship with cutting-edge technology, Germany is set to shape the future of global fashion.

Conclusion: Engineering Elegance for a Sustainable Tomorrow

Germany’s engineering excellence has cemented its position as a global leader in textile machinery, blending technical precision with creative vision. By driving sustainability and innovation, the German textile industry not only meets the needs of modern fashion but also sets new standards for the future.

As the demand for high-quality, sustainable textiles continues to grow, Germany’s role in shaping the global fashion landscape becomes even more significant. From technical textiles for industrial use to avant-garde fabrics for haute couture, German engineering is the thread that ties the industry together.

Titans of Technology: Germany’s Leading Players

Germany’s influence on textile machinery would be incomplete without acknowledging industry titans like Stoll, Groz-Beckert, and Karl Mayer, which are trailblazers in combining technological precision with fashion manufacturing innovation.

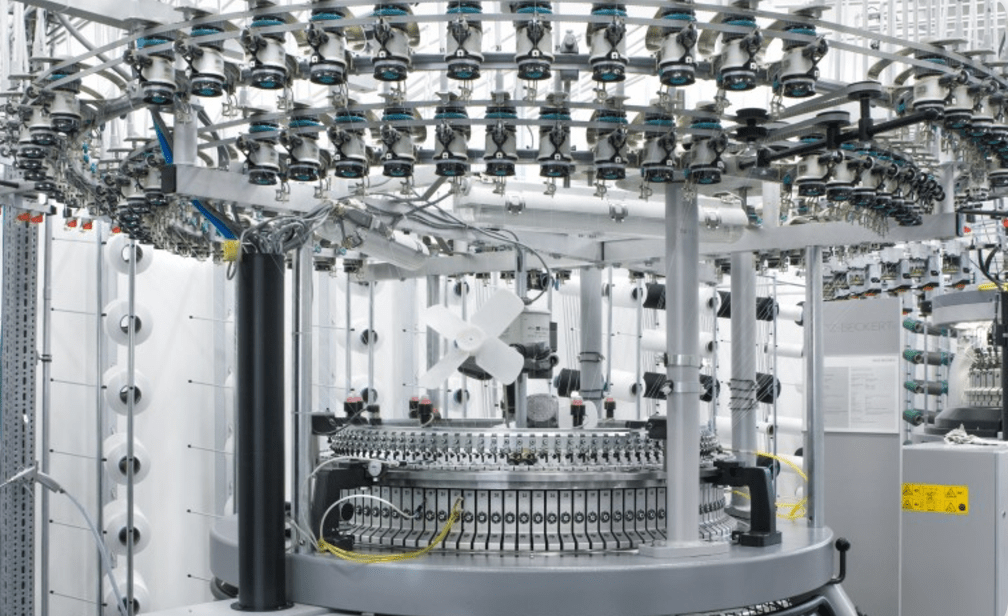

- Stoll: Famous for its flat-knitting machines, Stoll has revolutionized knitwear production, enabling the creation of intricate designs and seamless garments. Their machines are widely used in high-end fashion brands, pushing the boundaries of knitwear design.

- Groz-Beckert: This company specializes in manufacturing precision needles for industrial machines. With over 160 years of expertise, Groz-Beckert’s needles ensure exceptional accuracy in sewing, knitting, and weaving processes (Groz-Beckert, 2023).

Image by Groz-Beckert via https://www.groz-beckert.com/de/

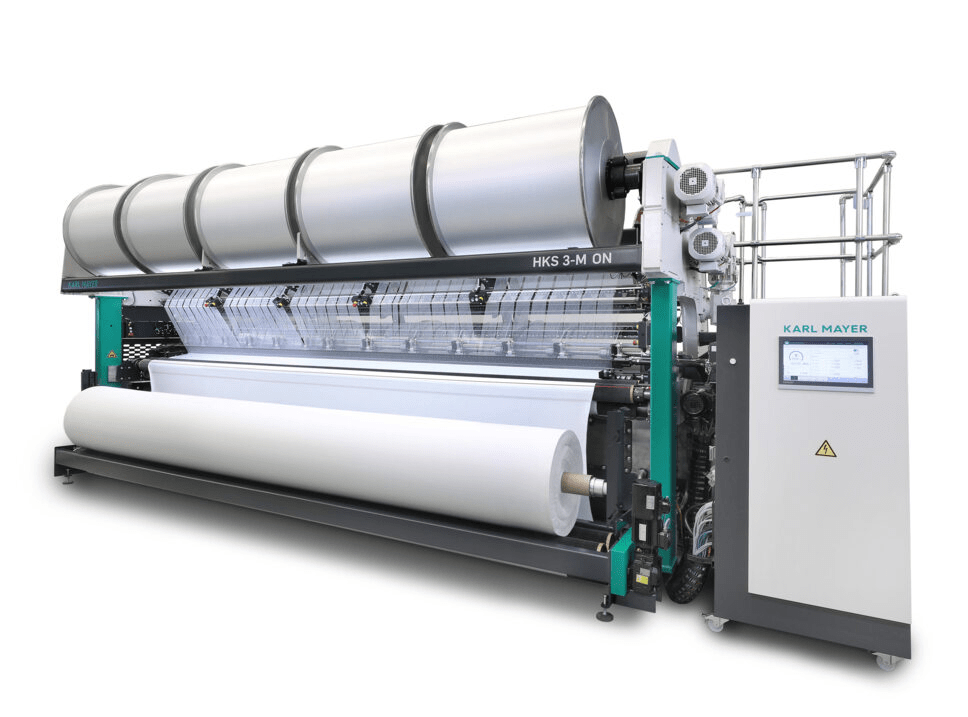

- Karl Mayer: Known for its warp-knitting and warp-preparation machines, Karl Mayer has developed technologies that optimize production speed and energy efficiency, ensuring it remains at the forefront of sustainable textile production (Karl Mayer, 2022).

Image by Karl Mayer via https://www.karlmayer.com/en/products/warp-knitting-machines/

These companies exemplify why German textile machinery is synonymous with innovation and reliability in the global market.

Greener Threads: How German Engineering Advances Sustainable Fashion

Germany’s textile machinery industry leads the way in eco-friendly solutions that align with the growing demand for sustainable fashion. From water-saving dyeing machines to recycling technologies, German engineering addresses the environmental challenges of textile production.

- Water-saving dyeing technologies: Innovations like the Thies iMaster minimize water consumption by 30–40%, significantly reducing the industry’s environmental footprint (Textile World, 2021).

Image by Thies iMaster via https://www.thiestextilmaschinen.com/product-portfolio/fabric-dyeing/imaster-family/imaster-h2o/

- Textile recycling technologies: Companies like Trützschler are pioneering machinery that facilitates the separation of fibers, making recycled materials viable for new fabric production (Trützschler, 2023).

Real-world examples highlight German machinery’s role in achieving sustainability. For instance, leading fashion brands have partnered with German firms to implement machines that reduce energy usage, lower carbon emissions, and optimize the utilization of raw materials.

Precision and Power: What Makes German Machines Stand Out?

German textile machinery sets the global benchmark for durability, efficiency, and customization. These machines are designed to handle diverse textile applications, from producing technical fabrics for industrial use to creating delicate materials for couture fashion.

- Durability: German engineering ensures that machines withstand prolonged usage while maintaining high precision, reducing downtime and repair costs.

- Customization: German manufacturers often work closely with clients to design machines tailored to specific production needs, enhancing their usability and appeal.

The combination of advanced technology and unwavering reliability makes German machines the gold standard for global textile production.

Spinning Globally: The Export Power of German Engineering

Germany’s textile machinery exports dominate the global market, with a strong presence in Asia, North America, and Europe. Countries like China, India, and Turkey rely heavily on German technology to improve their textile output.

- Collaborations: Partnerships between German firms and international brands, such as Adidas and H&M, illustrate the global reliance on German engineering for high-quality textile production.

- Economic impact: With exports contributing significantly to Germany’s GDP, the industry plays a vital role in sustaining the country’s economic health (VDMA, 2023).

This global reach underscores Germany’s strategic importance in driving innovation and meeting the growing demand for premium textiles worldwide.

Sewing the Future: Innovation in Action

Germany is at the forefront of cutting-edge developments in textile machinery, such as:

- AI-driven automation: Advanced machines integrate artificial intelligence to streamline production processes, predict maintenance needs, and reduce material waste.

- 3D knitting technology: Innovations in 3D knitting allow the creation of customized garments with minimal seams, reducing fabric waste and increasing garment durability.

- Smart textiles: These integrate electronics into fabrics for wearable technology, finding applications in sportswear, medical textiles, and fashion.

Additionally, German companies are spearheading efforts to create net-zero emissions machinery, aligning with global sustainability goals (VDMA, 2023).

Untangling Challenges: What Lies Ahead for German Machinery

Despite its successes, the German textile machinery industry faces challenges:

- Global competition: Emerging players like China offer machines at lower costs, pressuring German manufacturers to justify their premium prices.

- High cost of innovation: Developing advanced technologies requires significant investment, which can impact pricing and profit margins.

To remain competitive, German firms must continue to emphasize sustainability, focus on digital transformation, and strengthen their collaborative partnerships globally.

Conclusion: Engineering Tomorrow’s Trends

Germany’s blend of precision engineering and innovative spirit has positioned its textile machinery industry as a cornerstone of global fashion production. From advancing sustainable practices to enabling groundbreaking designs, German machines continue to shape the fashion industry.

Looking ahead, the integration of AI, sustainability, and advanced technologies will further solidify Germany’s leadership in the textile machinery sector. As the demand for more responsible fashion production grows, Germany’s technological solutions will remain crucial in knitting together the future of fashion.

References

- Fibre2Fashion. (2014). Global textile machinery market: A comprehensive analysis. Retrieved from https://www.fibre2fashion.com/industry-article/6539/global-textile-machinery-market-foresees-growth-prospects

- Glunz, S. (2020). Germany’s role in global textile machinery exports. International Trade Review. Retrieved from https://www.researchgate.net/publication/294694098_Germany_Leader_in_textile_machinery_manufacturing

- Groz-Beckert. (2023). Industry leaders in textile machinery. Retrieved from https://www.groz-beckert.com/en/news/specialized-press/itma-2023-%E2%80%93-groz-beckert-welcomes-over-7-000-customers-and-business-partners-at-its-trade-fair-booth.html

- Karl Mayer. (2022). Innovations in warp-knitting technologies. Retrieved from https://www.karlmayergroup.com/en/news-events/news/whats-new-in-warp-knitting/

- Textile World. (2021). The Sustainable “Fabric Of Our Lives”. Retrieved from https://www.textileworld.com/textile-world/features/2024/03/the-sustainable-fabric-of-our-lives/

- Trützschler. (2023). Pioneering recycling solutions in textile manufacturing. Retrieved from https://www.truetzschler.com/en/sustainability/sustainable-technologies/

- VDMA. (2023). VDMA Companies At ITMA Asia + CITME 2024: Smart Technologies For Green Textile Production. Retrieved from https://www.textileworld.com/textile-world/supplier-notes/2024/10/vdma-companies-at-itma-asia-citme-2024-smart-technologies-for-green-textile-production/

Hinterlasse einen Kommentar